The Company:

Leading manufacturer located in Fargo, ND supplying the tire and automotive equipment industry since its inception in 1917.

The Challenge:

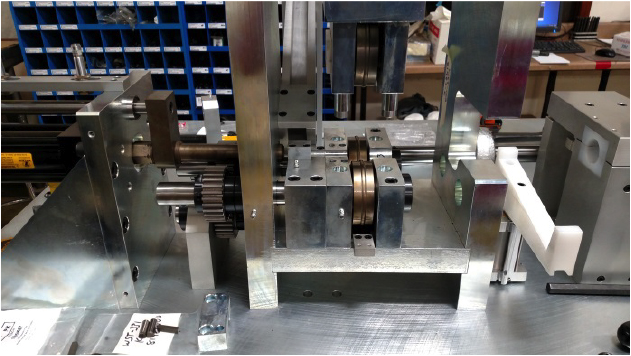

Improve manual cycle time for workers producing automotive equipment components. The project required the design and manufacturing of an advanced production machine for cellularization of components and JIT manufacturing. The machine need to press different steel plugs into different length heavy gauge steel tubings and automatically crimp the end of the tube to secure the plugs. Chuka-chuka single piece loading and hanedashi automatic unload method of the finished part were used. The machine had to allow for multiple part loading of steel plugs and automate the plug insertion into different length steel tubes. Machine requirements were to include ease of use, and meet all OSHA safety requirements.

The Solution:

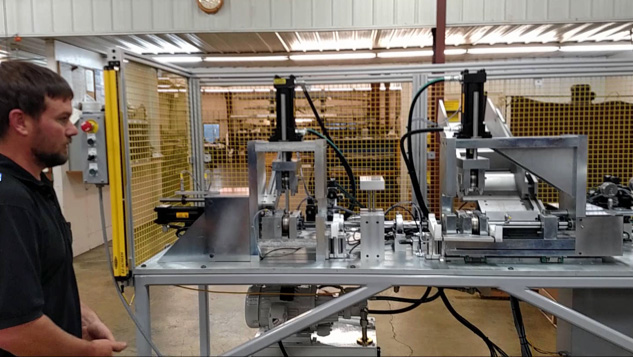

- Designed and manufactured a advanced manufacturing machine solution by collaborating with company manufacturing engineers and West Tool Enclosures.

- The final machine design used a practical engineering approach by collectively understanding the needs of the customer and the current production line processes.

- The RDR Services successful project implementation improved the safety, efficiency, and costs of manufacturing for the customer.

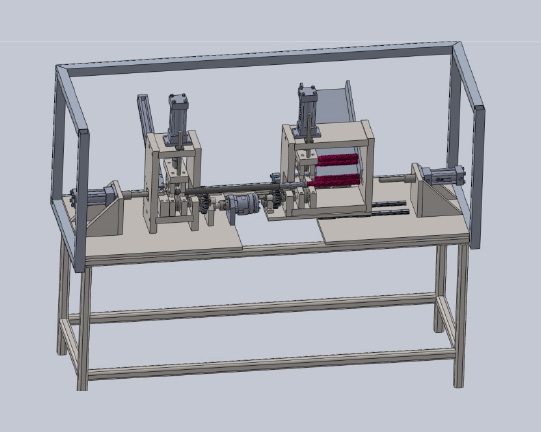

RDR Services used Solid Works 3D Solid Modeling application to synthesize concept and machine features for review and final approval by manufacturer and customer.

Crimping forces and component loading were analyzed to insure machine would meet the rigors of the plug insertion and crimping operation.

West Tool Enclosures provided the machine fabrication, assembly and testing services.