The Company:

Furniture manufacturer that offers solutions for the hospitality market.

The Challenge:

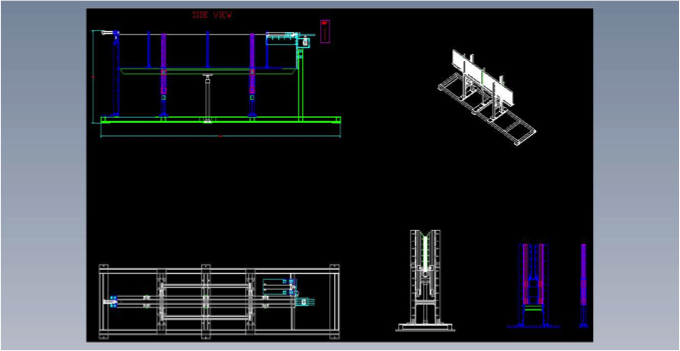

Convert one offering of custom furniture from steel fabrication to aluminum. The project required the design and manufacturing of a advanced production machine that replaced steel coil winding on the current production line. The machine needed to allow for stacking of banded aluminum strips being loaded with a fork lift during normal shift operations. The machine had to automate cut to length of aluminum strips moving into a roll forming operation prior to welding. Machine was to integrate with current production line, be easy to use, and meet all OSHA safety requirements.

The Solution:

RDR resources utilized modern CAD tools to transition initial concepts to manufacturing drawings and instructions for the machine, fabrication and assembly of the machine.

RDR resources used their extensive experience in the operations this machine needed to perform to insure the machine was simple, reliable and functional.

The same experienced RDR resources that were involved in the design and the development of the machine were “hands on” in the final assembly and test.