The Company:

A leading hearth product manufacturer.

The Challenge:

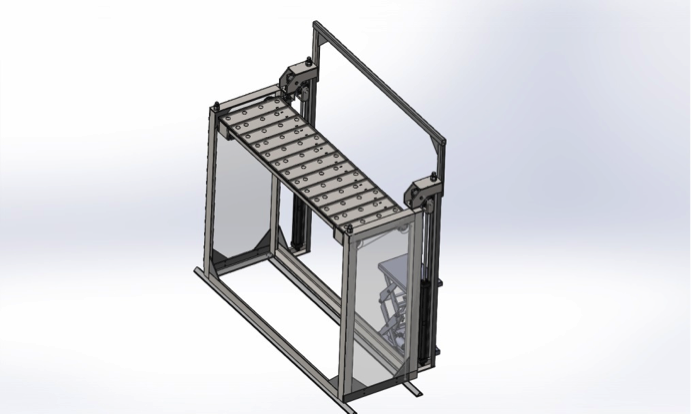

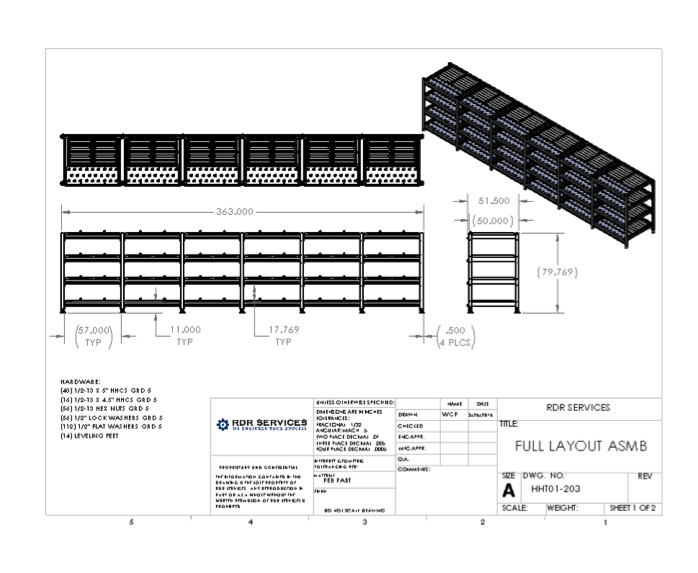

Project consists of the design, engineering, and manufacturing of a Multiple Level Modular Die Storage and Transfer System to store dies sets in a variety of sizes as defined by the customer. The project would require a custom, self- leveling, mobile lift cart for increased vertical travel and reduced lowered height. Lift is provided with moveable up/down stop gate on each side of lift to secure die set on lift during transport. Lift would be hydraulically operated and be mounted on v-grooved wheels and roll on existing angle iron tracks. Storage system is to integrate with current production line, be easy to use, and meet all OSHA safety requirements.

The Solution:

- Designed and manufactured an advanced manufacturing solution by collaborating with company engineers and managers.

- The final solution used a practical engineering approach by collectively understanding the needs of the customer and the current production line processes.

- The RDR Services successful project implementation improved the safety, efficiency, and costs of manufacturing for the customer.

RDR Services team utilized solid works 3D solid modeling to provide visualization for custom input and approval.

RDR Services turned concept into reality and once design concept was approved, implemented the manufacturing and testing program.

Customer participated in final build, test, and approval to project completion.